Ahịrị mmepụta akpa nri

Isi paramita

| Ihe | Nkeji | Oke | Okwu |

| Nlereanya | FS-FPP75-90 | ||

| Ngwa ndị ọdabara | GPPS granule | ||

| Ọkpụrụkpụ nke ngwaahịa | mm | 1-4 | |

| Ogologo mpempe akwụkwọ | mm | 540–1100 | |

| Ọnụọgụ ụfụfụ | 12-20 | ||

| Nnukwu arọ nke ngwaahịa | Kg/m³ | 50-83 | |

| Thermal conductivity nke ngwaahịa | W/mk | 0.021-0.038 | |

| Mpụta | n'arọ/h | 70-90 | |

| Enyere ike | Kw | 140 | |

| Ịnye ọkụ | 3 nkeji 380V / 50Hz | ||

| Akụkụ mpụga | mm | 24000×6000×2800 | |

| Ibu igwe zuru oke | Tọn | Ihe dịka10 |

Ⅰ 75/90 PS ụfụfụ mpempe akwụkwọ extrusion akara gụnyere ihe ndị a

1. Usoro nri na-akpaghị aka

1. Ụdị nri

Nri gburugburu

2. Isi paramita

| Ikike hopper nke igwekota (kg) | 300 |

|

| Ike moto nke igwekota (kw) | 3 | |

| Ike inye nri (kg/h) | 200 | |

| Ike moto nke feeder (kw) | 1.5 |

2 Nke mbụ ogbo extruder

1. Ịghasa na gbọmgbọm ihe

38CrMoAlA ọgwụgwọ nitrogen

2. Isi ụdị moto

AC-moto nwere ndị ntụgharị ugboro ugboro

⑶ Onye na-ebelata ọsọ ọsọ

Extruder raara onwe ya nye reducer, ike eze n'elu, elu torque, na obere mkpọtụ

⑷ Igwe ọkụ

Igwe ọkụ alumini nke nkedo, ihe nrụpụta enweghị kọntaktị steeti siri ike, njikwa okpomọkụ nwere ọgụgụ isi

⑸ Teknụzụ paramita

| Ike ịnya ụgbọ ala (kw) | 37 |  |

| Dayameta nke skru bolt (mm) | Φ70 | |

| Oke L/D nke skru bolt | 32:1 | |

| Ntugharị kachasị nke skru (rpm) | 60 | |

| Ọnụọgụ mpaghara kpo oku | 7 | |

| Ike ikpo oku (kw) | 28 |

4 igwe na-adịghị akwụsị akwụsị hydraulic akpaaka dochie nzacha usoro

hydraulic anaghị akwụsị ngwa ngwa netwọk na-agbanwe ngwaọrụ

Isi paramita

| Oil mgbapụta moto ike (kw) | 4 |   |

| Oil mgbapụta max mgbali (Mpa) | 20 | |

| Filter net quantity (iberibe) | 4 | |

| Ike ikpo oku (kw) |

5 Nke abụọ ogbo extruder

1. Ịghasa na gbọmgbọm ihe

38CrMoAlA ọgwụgwọ nitrogen

2. Isi ụdị moto

AC-moto nwere ndị ntụgharị ugboro ugboro

⑶ Onye na-ebelata ọsọ ọsọ

Extruder raara onwe ya nye reducer, ike eze n'elu, elu torque, na obere mkpọtụ

⑷ Igwe ọkụ

Igwe ọkụ alumini nke nkedo, ihe nrụpụta enweghị kọntaktị steeti siri ike, njikwa okpomọkụ nwere ọgụgụ isi

⑸ Ntu oyi na ụdị mbelata okpomọkụ

Circulating mmiri jụrụ, akpaka uzo usoro.

⑹ Nka nka

| Ike ịnya ụgbọ ala (kw) | 45 |  |

| Dayameta nke skru bolt (mm) | Φ90 | |

| Oke L/D nke skru bolt | 34:1 | |

| Ntugharị kachasị nke skru (rpm) | 30 | |

| Ọnụọgụ mpaghara kpo oku | 8 | |

| Ike ikpo oku (kw) | 40 |

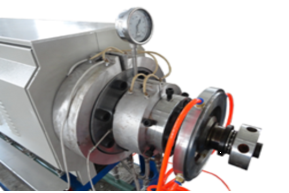

6 Extruder isi na ebu

1. Ọdịdị

Gburugburu nke extruder isi, ebu ọnụ nwere ike ịgbanwe , isi na a nrụgide nlele na nrụgide mmepụta mkpu ngwaọrụ.Igwe kpo oku isi na mmiri jụrụ oyi .

2. Ihe

Oke: 0.025μm

Ngwá ọrụ dị elu ígwè, okpomọkụ a na-emeso, ọwa mmiri na-asọ asọ: Ra0.025μm

⑶ Isi data teknụzụ

| Dayameta nke ebu orifice | dịka nkwekọrịta iwu siri dị |  |

| Ọnụọgụ mpaghara njikwa okpomọkụ | 2 | |

| Ịdị mma nke njikwa okpomọkụ (℃) | ±1 | |

| Ike ikpo oku (kw) | 5 |

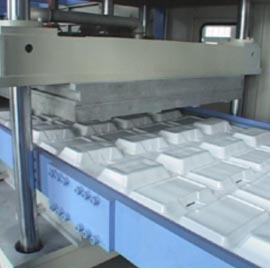

7 Ịkpụzi usoro jụrụ oyi na ịkpụ

1. Ịkpụzi ụdị: ịkpụ gbọmgbọm

2. Ntu oyi style: ịkpụzi gbọmgbọm cools na mmiri na mpụga ifufe-mgbanaka

⑶ Structure: ịkpụzi gbọmgbọm, ịcha mma na akụrụngwa akụrụngwa

⑷ Isi teknuzu paramita

| Ịkpụzi nha gbọmgbọm (mm) | Dị ka nkwekọrịta iwu si dị |  |

| Ike ikuku (kw) | Nkebi ahịrịokwu atọ 0.55 |

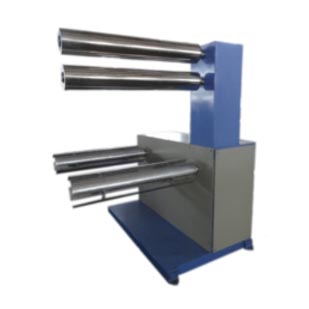

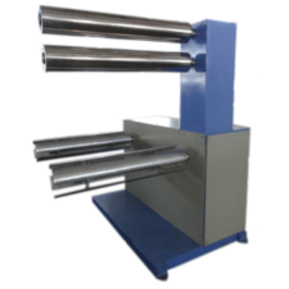

8 Sistemụ na-adọkpụ

1. Na-adọkpụ ụdị: anọ-roller yiri sere

2. Ụdị moto ịkwọ ụgbọ ala: AC-motor, mgbanwe mgbanwe ọsọ ọsọ ọsọ, mgbanwe ọsọ ọsọ

⑶ Isi paramita

| Ọnụ ọgụgụ nke roller (iberibe) | 4 |  |

| Mpempe akwụkwọ mpịakọta (mm) | Φ260×1300 | |

| Ike moto (kw) | 1.5 |

9 Electrostatic mkpochapụ usoro

| Nabata tod ụdị ion mkpanaka electrostatic mkpochapụ usoro, na-arụ ọrụ volt bụ 7KV n'elu, nwere ike na-emepụta elu dị irè ma dị ike ion ifufe, n'ụzọ dị irè wepụ electrostatic ize ndụ. |  |

10 Sistemụ ikuku

1. Ụdị

Ụdị ogwe ikuku nke nwere ogwe aka abụọ

2. Isi teknuzu paramita

| Ibu ibu (kg) | Kachasị 40 |  |

| Dayameta mkpuchi mkpuchi (mm) | Nke kachasị 1100 | |

| Njikwa ogologo | Njikwa counter mita, gbanwee ogologo | |

| moto ịnya ụgbọ ala | Torque moto 8n.m × 4sets |

11 Usoro njikwa ọkụ eletrik

| extruder kpo oku akara kabinet | Otu setịpụ |   |

| Nke abụọ ogbo extruder kpo oku akara kabinet | Otu setịpụ | |

| winding akara kabinet | Otu setịpụ |

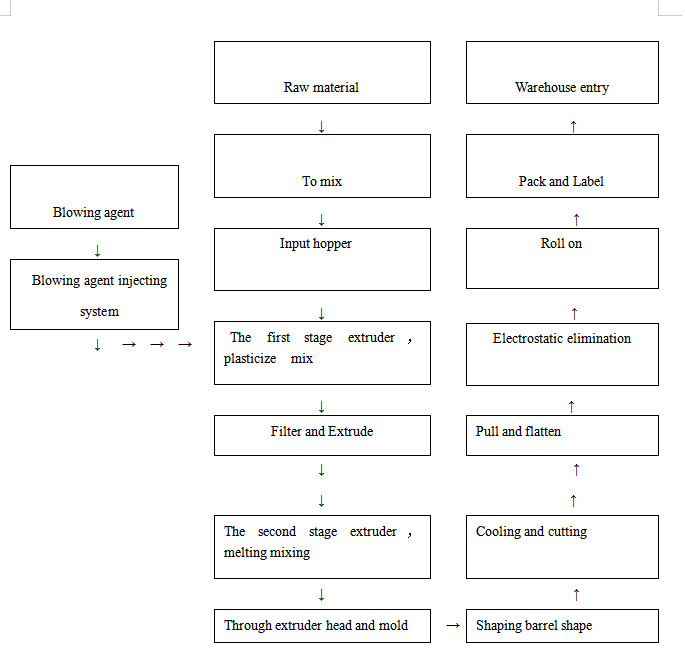

Ⅲ Mputa eruba eserese

Ⅳ Nkọwa nke ahịrị mpempe akwụkwọ ụfụfụ

A. Usoro nri akpaaka

1. Ụdị nri

Nri gburugburu

2. Isi paramita

| Ikike hopper nke igwekota (kg) | 300 |

| Ike moto nke igwekota (kw) | 3 |

| Ike inye nri (kg/h) | 200 |

| Ike moto nke feeder (kw) | 1.5 |

B. Nke mbụ ogbo extruder

1.Screw na gbọmgbọm ihe

38CrMoAlA ọgwụgwọ nitrogen

2. Isi ụdị moto

AC-moto nwere ndị ntụgharị ugboro ugboro

3. Onye na-ebelata ọsọ ọsọ

Extruder raara onwe ya nye reducer, ike eze n'elu, elu torque, na obere mkpọtụ

4. Igwe ọkụ

Igwe ọkụ alumini nke nkedo, ihe nrụpụta enweghị kọntaktị steeti siri ike, njikwa okpomọkụ nwere ọgụgụ isi

5. Nka na ụzụ paramita

| Ike ịnya ụgbọ ala (kw) | 37 |

| Dayameta nke skru bolt (mm) | Φ70 |

| Oke L/D nke skru bolt | 32:1 |

| Ntugharị kachasị nke skru (rpm) | 50 |

| Ọnụọgụ mpaghara kpo oku | 7 |

| Ike ikpo oku (kw) | 28 |

C. Sistemụ ịgbanye onye na-akụ ihe

1. Ụdị mgbapụta

Plunger ụdị nkenke dị elu na mgbapụta nrụgide dị elu, iji dabaa valvụ otu ụzọ iji chịkwaa, a na-achịkwa olu injection site na ebuli elu.

2. Isi teknuzu paramita

| Ụdị ihe ọfụfụ | butane ma ọ bụ LPG |

| Mgbapụta mgbapụta mita | 40 (L.H) |

| Ịgba ọgwụ dị elu | 30 (Mpa) |

| Nleba nrụgide | 0-40 (Mpa) |

| Ike moto | 3 (kw) |

D. Igwe anaghị akwụsị akwụsị hydraulic akpaaka dochie nzacha usoro

Ngwa hydraulic na-agbanwe net ngwa ngwa

Isi paramita

| Oil mgbapụta moto ike | 4 (kw) |

| Oil mgbapụta max mgbali | 20 (Mpa) |

| Nzacha ọnụọgụgụ | 4 (ibe) |

| Ike ikpo ọkụ | 8 (kw) |

E. Nke abụọ ogbo extruder

1. Ịghasa na gbọmgbọm ihe

38CrMoAlA ọgwụgwọ nitrogen

2. Isi ụdị moto

AC-moto nwere ndị ntụgharị ugboro ugboro

3. Onye na-ebelata ọsọ ọsọ

Extruder raara onwe ya nye reducer, ike eze n'elu, elu torque, na obere mkpọtụ

4. Igwe ọkụ

Igwe ọkụ na-ekpo ọkụ nke alumini, ihe nrụpụta na-enweghị njikọ nke steeti siri ike, njikwa ọnọdụ okpomọkụ nwere ọgụgụ isi , Ngwa mmiri jụrụ oyi na kpo oku.

5. Ụdị oyi na okpomọkụ-mbelata

Circulating mmiri jụrụ , akpaka uzo usoro.

6. Nka na ụzụ paramita

| Ike ịnya ụgbọ ala (kw) | 45 |

| Dayameta nke skru bolt (mm) | Φ120 |

| Oke L/D nke skru bolt | 34:1 |

| Ntugharị kachasị nke skru (rpm) | 50 |

| Ọnụọgụ mpaghara kpo oku | 8 |

| Ike ikpo oku (kw) | 40 |

F. Extruder isi na ebu

1. Ọdịdị

Gburugburu nke extruder isi, ebu ọnụ nwere ike ịgbanwe , isi na a nrụgide nlele na nrụgide mmepụta mkpu ngwaọrụ.Igwe kpo oku isi na mmiri jụrụ oyi .

2. Ihe onwunwe Ra0.025μm:

Ngwá ọrụ dị elu ígwè, okpomọkụ a na-emeso, ọwa mmiri na-asọ asọ: Ra0.025μm

3. Isi teknụzụ data

| Dayameta nke ebu orifice | Dị ka nkwekọrịta iwu si dị |

| Ọnụọgụ mpaghara njikwa okpomọkụ | 1 |

| Ịdị mma nke njikwa okpomọkụ | ±1 (℃) |

| Ike ikpo ọkụ | 5 (kw) |

G. Ịkpụzi usoro jụrụ oyi na ịkpụ

1. Ịkpụzi ụdị: ịkpụ gbọmgbọm

2. Ntu oyi style: ịkpụzi gbọmgbọm cools na mmiri na mpụga ifufe-mgbanaka

3.Structure: ịkpụzi gbọmgbọm, ịcha mma na akụrụngwa akụrụngwa

4. Isi teknuzu paramita

| Ịkpụzi nha gbọmgbọm (mm) | Dị ka nkwekọrịta iwu si dị |

| Ike ikuku (kw) | Nkebi ahịrịokwu atọ 0.55 |

H. Usoro ịdọrọ

1.Pulling style: anọ-roller yiri sere, mpikota onu na ikuku mbanye

2.Driving moto ụdị: AC-motor, ugboro mgbanwe mgbanwe ọsọ modulation, ọsọ reducer mgbanwe ọsọ

3. Isi paramita

| Ọnụ ọgụgụ nke roller (iberibe) | 4 |

| Mpempe akwụkwọ mpịakọta (mm) | Φ260×1300 |

| Ike moto (kw) | 1.5 |

I. Electrostatic mkpochapụ usoro

Nabata tod ụdị ion mkpanaka electrostatic mkpochapụ usoro, na-arụ ọrụ volt bụ 7KV n'elu, nwere ike na-emepụta elu dị irè ma dị ike ion ifufe, n'ụzọ dị irè wepụ electrostatic ize ndụ.

J. Usoro ikuku

1. Ụdị

Ụdị ogwe ikuku nke nwere ogwe aka abụọ

2. Isi teknuzu paramita

| Ibu ibu (kg) | Kachasị 40 |

| Dayameta mkpuchi mkpuchi (mm) | Nke kachasị 1100 |

| Njikwa ogologo | Njikwa counter mita, gbanwee ogologo |

| moto ịnya ụgbọ ala | Torque moto 8n.m × 2 tent |

K. Usoro njikwa ọkụ eletrik

kpo oku akara kabinet nke mbụ ogbo extruder: otu set

kpo oku akara kabinet nke abụọ ogbo extruder: otu set

Kabinet njikwa ikuku: otu set